Winemaking and Tamjanika: The tricks of the trade

The unspoken secrets of making a perfect wine

Growing and the first sampling of grapes takes place in the vineyards

A demanding process that lasts from January when the pruning starts until September when the grapes are tasted and the moment of harvest is determined. Every day, winegrowers strive to achieve the set goals, which are the impeccable health of the vines and the grapes themselves, a limited yield of a maximum of 1.5 kg per vine and harvesting at the ideal moment, all using numerous viticultural techniques.

Harvest

As soon as all pre-defined parameters are met, the harvest begins. It is performed exclusively at night or in the early morning, ie. before sunrise when a large number of pickers are moving. The goal in the harvest is perfect timing and to pick at lower temperature as well as to keep the grapes cooled in order to preserve the incredible aromatic potential of Tamjanika.

Transfer

Immediately after picking, the grapes are transported to the cellar, where they are cooled and processed at a controlled temperature of around 5ºC

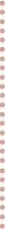

Processing

Since the harvest is done manually, no further selection of bunches is needed because the selection is done in the vineyard itself. The grapes are poured directly from the grape crates into a destemmer that separates steams from the berries and then gently crushes the berries, which crack slightly and open up to better squeeze the grape juice during pressing.

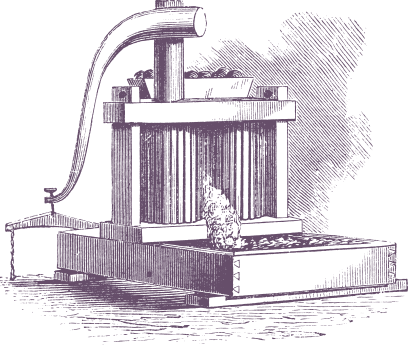

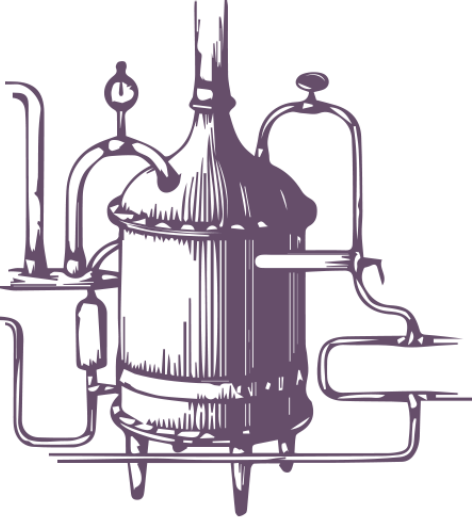

Maceration and pressing

From desteamer, skins and liquid are pumped to the press where the maceration takes place for about 30-45 minutes and then grapes are pressed to a pressure of 1 bar, ie. the maximum randman is set at 60%.

Fermentation

After precipitating the grape juice in stainless steel at 6ºC, it is "removed" from the sediment and pumped to an oak wood fermenter where the temperature slowly and naturally rises to 12ºC. When the juice reaches planed temperature selected yeasts are added. By the action of yeast, the juice passes into the wine in a controlled process that lasts around 15 days.

Aging and èlevage

When fermentation process is finished, young wine is transferred to stainless steel vessels where „silent“ fermentation continues, and in the following months other processes of wine elevage are performed, where it is racked with aeration, clarified and where we follow the growth of our „child“. A smaller percentage of wine is aged in barrel oak barrels (barrique) in order to add even more complexity to the aromatic profile.

Filtration

When the wine becomes mature we prepare it for bottling by filtering it to obtain the crystal clarity that we all like to see in the glass.

Bottling

After filtering, semi-automatic bottling is performed with strict control. Since the wine has experienced stress after the filter and all the processes before entering the bottle, they are placed horizontally and left in a dark room to rest (at a temperature of about 13ºC) for at least 2 months. Only after a detailed organoleptic analysis the wine is released to find it’s way to his admirers.